When you picture construction in the United Arab Emirates, your mind likely conjures images of iconic skylines rising from the desert—the Burj Khalifa, the Museum of the Future—all monuments to human ingenuity built with traditional on-site methods. But a quiet revolution is taking place, one that’s shifting the very foundation of how buildings are created. This revolution isn’t happening on dusty construction sites, but inside climate-controlled, technologically advanced factories. This is the world of prefabricated construction in the UAE, a method poised to solve some of the industry’s biggest challenges.

Traditional construction, for all its triumphs, often battles tight deadlines, rising material costs, skilled labor shortages, and significant environmental waste. As the UAE pushes towards ambitious goals for sustainability and efficiency, a new approach is not just an option, but a necessity. This guide explores the rise of off-site manufacturing, delving into what it is, its game-changing benefits, and whether it truly represents the future of building in this dynamic region.

What Exactly Is Prefabricated Construction?

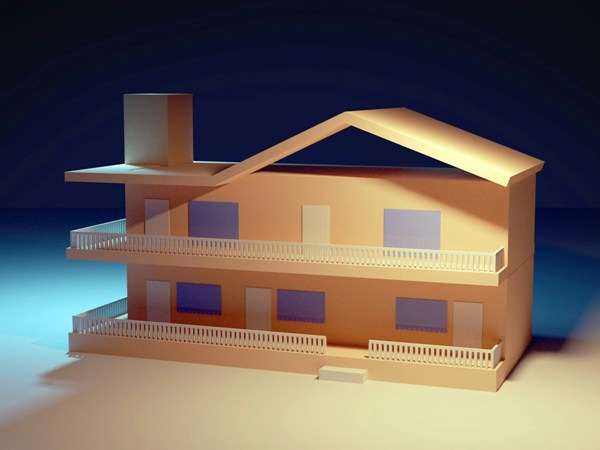

At its core, prefabrication is a simple concept that you’re already familiar with. Think of it like assembling a high-end piece of Swedish furniture versus building a table from raw lumber in your backyard. Instead of bringing all the raw materials to a construction site, you manufacture components of a building in a specialized factory and then transport them to the site for assembly. This umbrella term, often called off-site construction UAE, covers several methods:

- Component Systems: Manufacturing individual elements like wall panels, floor systems, or precast concrete facades in a factory. These are then fitted together on-site.

- Panelized Systems: Entire wall or floor panels are factory-built, often complete with insulation, wiring conduits, and window openings, and then craned into place.

- Modular Construction: This is the most complete form of prefabrication. Entire three-dimensional sections of a building—a hotel room, a bathroom pod, a classroom—are built, finished, and even furnished in a factory. These “modules” are then transported to the site, stacked, and connected. This is the methodology driving the conversation around modular construction Dubai.

Why Now? The Driving Forces Behind Prefabrication’s Rise in the UAE

Prefabrication isn’t a new idea, but its moment has truly arrived in the UAE, thanks to a perfect storm of government vision, market demand, and technological advancement.

Government Vision and Initiatives

The UAE’s leadership has consistently championed innovation. Ambitious goals like the UAE Net Zero by 2050 Strategic Initiative and the Dubai 3D Printing Strategy—which aims to have 25% of new buildings printed by 2030—create a fertile ground for technologies that are efficient and sustainable. Prefabrication shares the same DNA as 3D printing: digitizing design, automating manufacturing, and reducing waste.

The Need for Speed and Efficiency

The UAE’s development is famously fast-paced. Mega-projects with immovable deadlines demand construction methods that are quick and reliable. Off-site construction decouples the manufacturing timeline from the on-site preparation timeline. While foundations are being laid on site, modules are being simultaneously built in the factory, effectively cutting project duration in half in many cases.

Quest for Quality and Skilled Labor

A factory environment allows for a level of quality control that is difficult to achieve on an open construction site. Work is performed in optimal conditions, free from weather disruptions, and subject to rigorous, multi-stage inspections. This factory-based approach also helps address the regional challenge of finding and retaining highly skilled on-site labor for certain trades.

The Game-Changing Benefits of Prefabrication

When you shift from on-site chaos to off-site control, the advantages are profound. The benefits of prefabrication touch every critical aspect of a project.

Drastically Reduced Timelines

As mentioned, the ability to run site work and fabrication in parallel is the biggest time-saver. This can reduce overall project timelines by 30-50%. For a developer, this means a faster return on investment. For a school or hospital, it means serving the community months, or even years, sooner.

Superior Quality and Consistency

Every component is built to precise specifications using automated machinery in a controlled environment. This results in tighter tolerances, better seals, and a higher-quality finish. The first module built is identical to the last, ensuring a level of consistency that is nearly impossible to replicate with traditional methods.

Enhanced Safety and Security

Construction sites are inherently hazardous environments. By moving up to 80% of the labor activity to a factory, you dramatically reduce the risks of falls, on-site accidents, and other common hazards. According to industry analysis, modular construction can improve safety records by over 70%, a statistic supported by global safety bodies like the Occupational Safety and Health Administration (OSHA) which advocate for controlled work environments.

Significant Waste Reduction and Sustainability

This is perhaps one of the most compelling benefits. Factories can optimize material usage, leading to a reduction in construction waste by up to 90%. This not only saves money but is also a massive win for the environment. It’s a direct contribution to our commitment to sustainable construction and aligns perfectly with the UAE’s green building goals.

Sierra Turnkey Contracting and Sustainability

Cost Predictability

While the initial cost of prefabrication isn’t always lower, the final cost is far more predictable. By minimizing the risks of weather delays, labor issues, and on-site errors, you can virtually eliminate the costly budget overruns that plague many traditional projects.

Key Takeaways at a Glance

| Metric | Traditional Construction | Prefabricated Construction |

|---|---|---|

| Speed | Sequential process, weather-dependent | Parallel process (site + factory), up to 50% faster |

| Quality | Variable, dependent on site conditions and labor skill | Consistent, high-quality, factory-controlled |

| Safety | Higher risk, multiple on-site hazards | Significantly safer, controlled factory environment |

| Waste | High material wastage (up to 30%) | Minimal waste (as low as 2-5%) |

| Cost | Prone to budget overruns and delays | High cost predictability, fewer surprises |

Challenges and Hurdles to Widespread Adoption

Despite its clear advantages, the road to making prefabricated construction in the UAE the norm has a few speed bumps.

- Perception and Mindset: The biggest hurdle is overcoming the outdated stigma that “prefab” means low-quality or temporary. Educating developers and consumers about the high-tech, durable nature of modern modular building is key.

- Logistics and Transportation: Moving large, three-dimensional modules from a factory to a congested urban site requires careful planning and can be a logistical challenge.

- Initial Capital Investment: Setting up a large-scale, automated prefabrication facility requires a significant upfront investment in technology and real estate.

- Design Flexibility: While technology is making modular design incredibly flexible, it still requires more upfront design commitment than traditional methods, where changes can often be made on the fly (albeit at a cost).

Frequently Asked Questions

Is prefabricated construction cheaper than traditional building in the UAE?

Not necessarily on a direct cost-per-square-meter basis. The primary financial benefit comes from “soft costs”: faster ROI due to earlier completion, reduced labor costs, and the elimination of costly delays and rework. For many commercial projects, the time saved is worth more than any initial cost difference.

Can you build high-rise towers using modular construction Dubai?

Yes. While full modular high-rises are still emerging, hybrid approaches are common. This involves using a traditional concrete core for the structure while using prefabricated and modular components like bathroom pods, apartment units, and facade panels to rapidly build out the tower.

How durable are prefabricated buildings in the UAE’s climate?

They are just as durable, if not more so. Because they are built with high-quality materials to precise standards in a controlled environment, they are often better sealed and more resilient to harsh weather conditions. The materials used are the same as in traditional construction (concrete, steel, glass) but are assembled more efficiently.

Conclusion: Assembling the Future of Construction in the UAE

So, is prefabricated construction in the UAE the future of building? The answer is a resounding yes. It may not replace traditional methods entirely, especially for highly bespoke or monumental structures, but it will undoubtedly become an essential, dominant part of the industry. It directly addresses the region’s core needs for speed, quality, safety, and sustainability.

The future of construction in UAE is a hybrid one, where the precision of the factory and the adaptability of the site work in perfect harmony. As technology continues to advance, the line between manufacturing and construction will blur, leading to smarter, faster, and greener buildings. You can already see how we’ve implemented these advanced methods in our latest projects.

Are you ready to build faster, smarter, and more sustainably? Contact our experts today to discuss how modular and prefabricated solutions can bring your next project to life with unparalleled efficiency and quality.

Photo by Ashin K Suresh on Unsplash